MIM products

MIM products

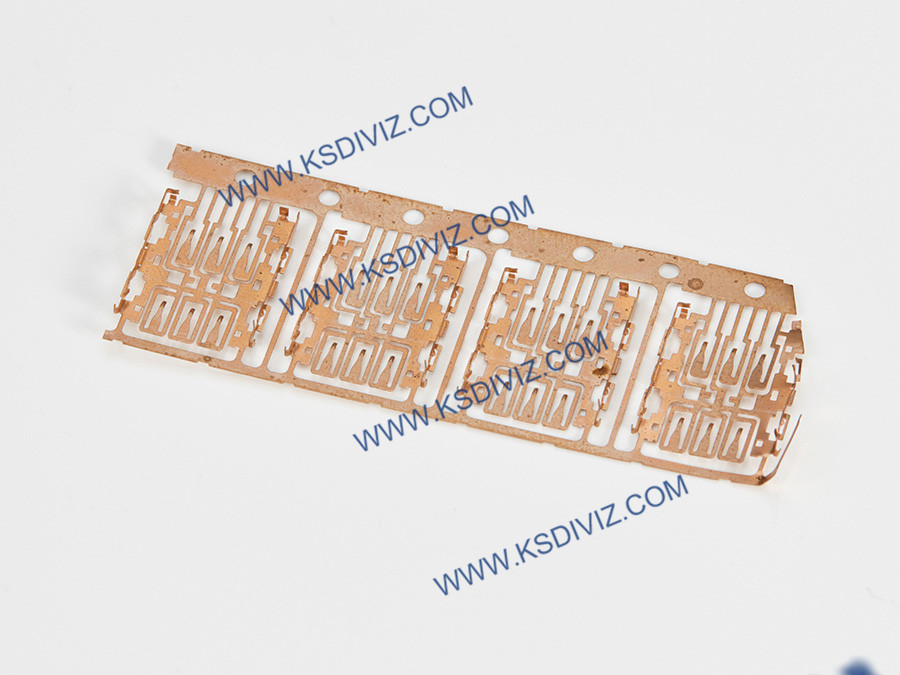

RF Antenna products

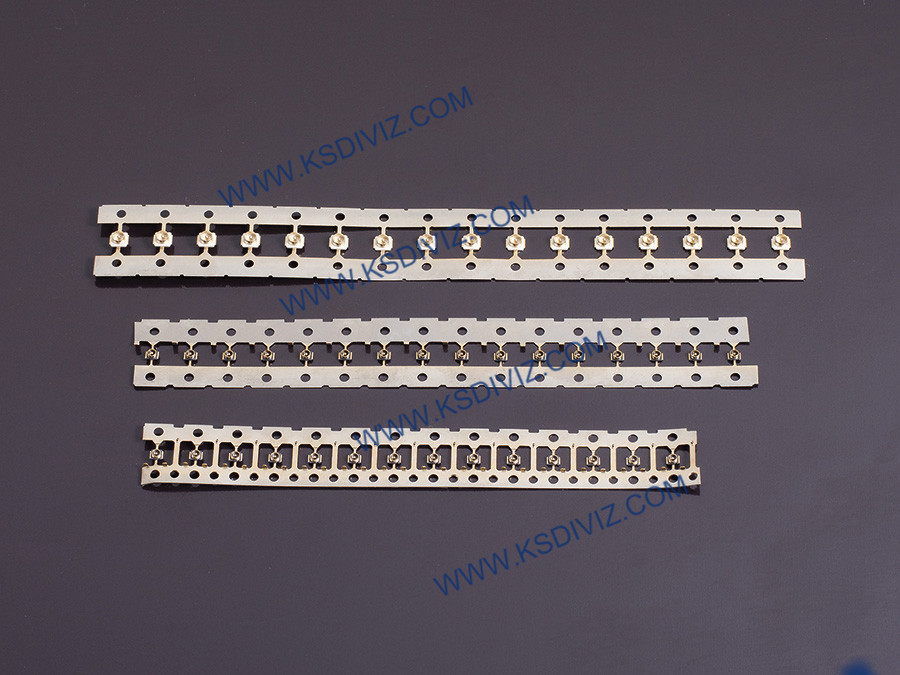

Stamping products

Wearable products

Industrial control products

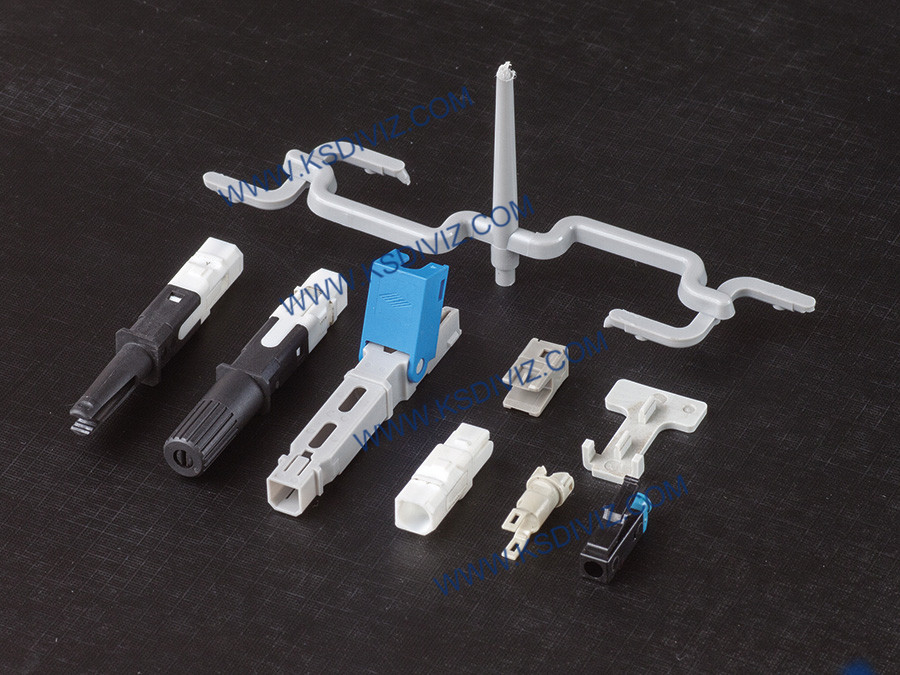

Optical fiber communication …

Optical products

Screw machine

iphone peripheral products

General organization product…

Electronic control center cl…

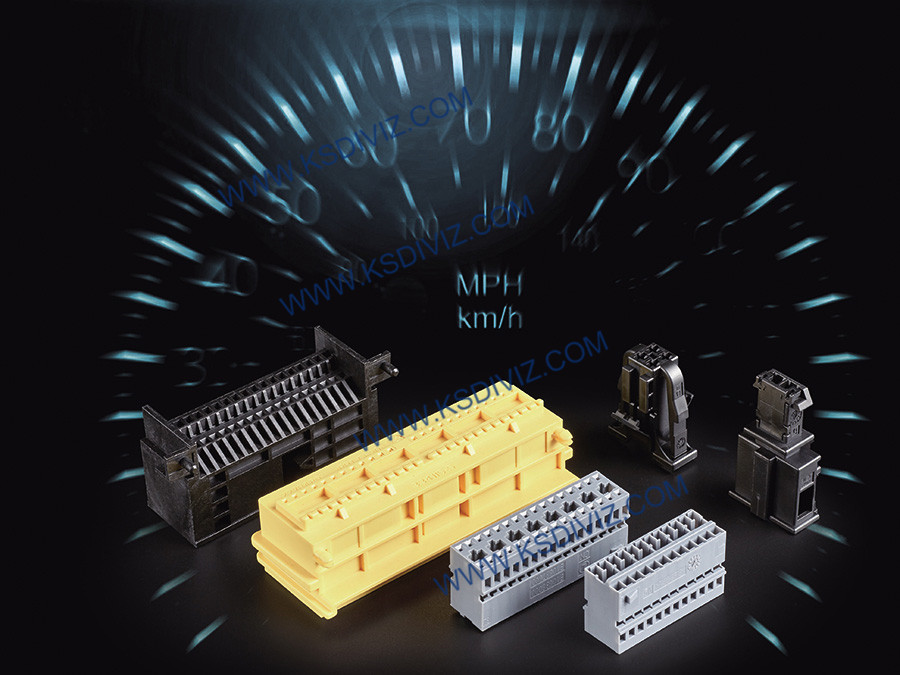

Automobile sensor

Automotive products

Acoustic products

Medical device products

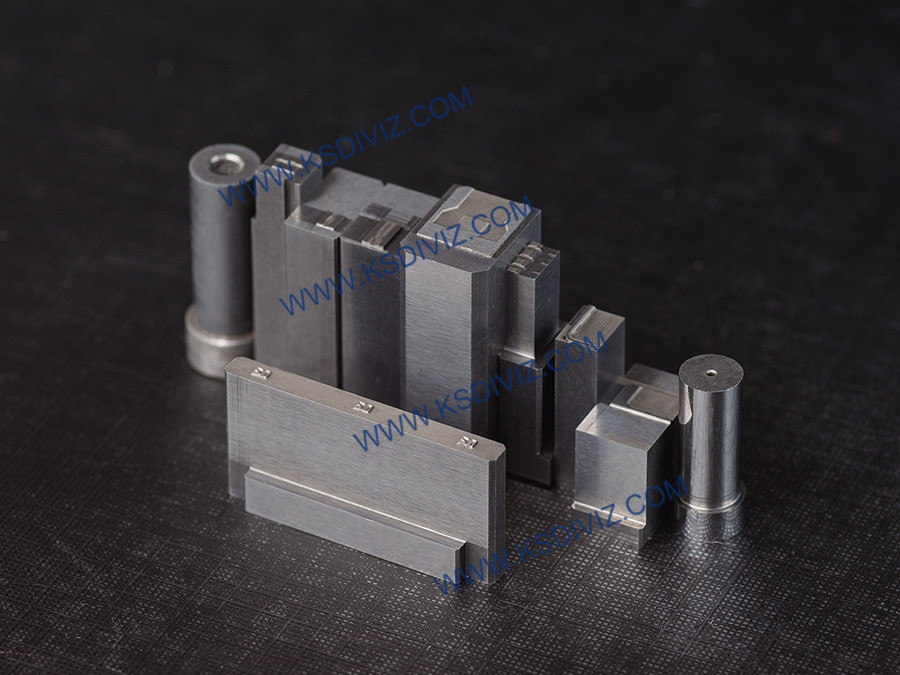

RF Antenna mold parts

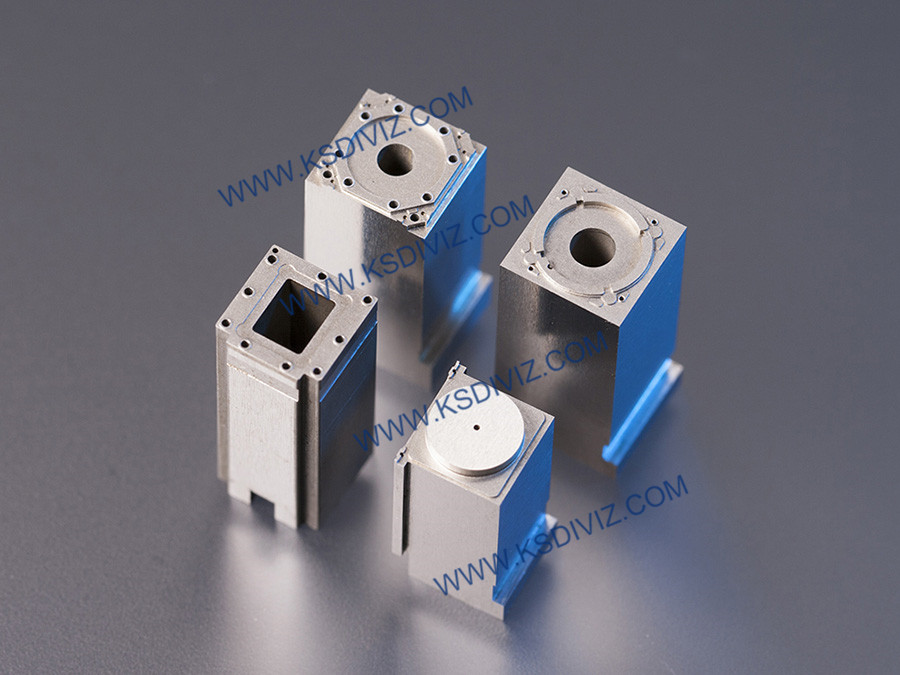

Mould parts for optical prod…

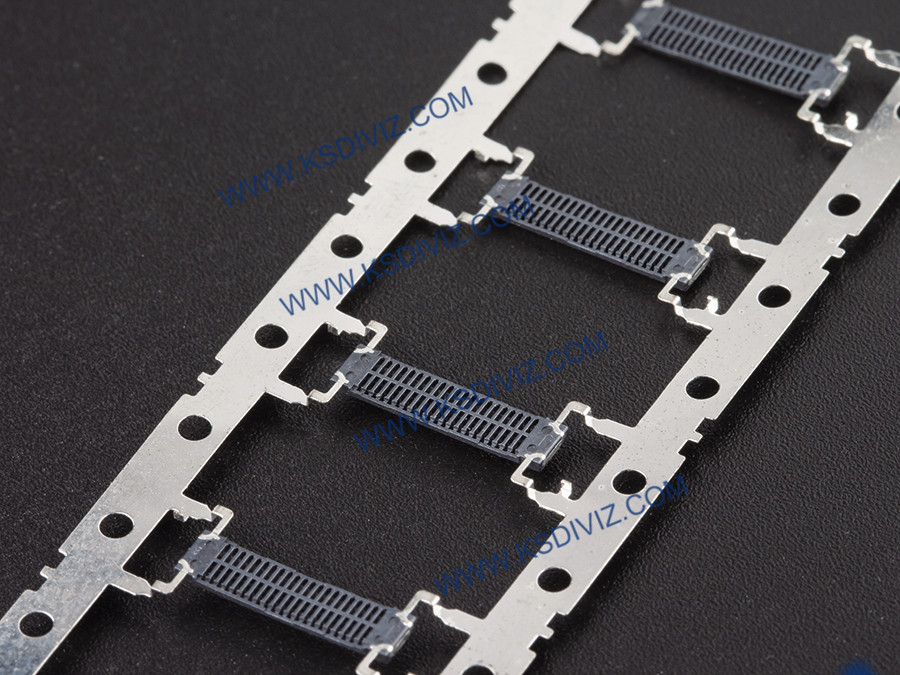

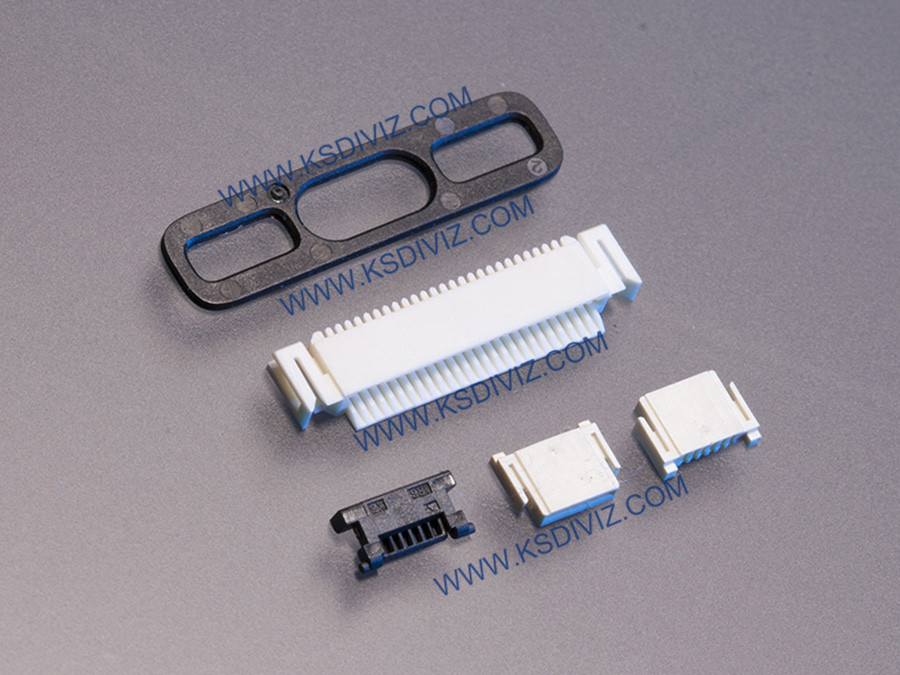

Connector mold parts

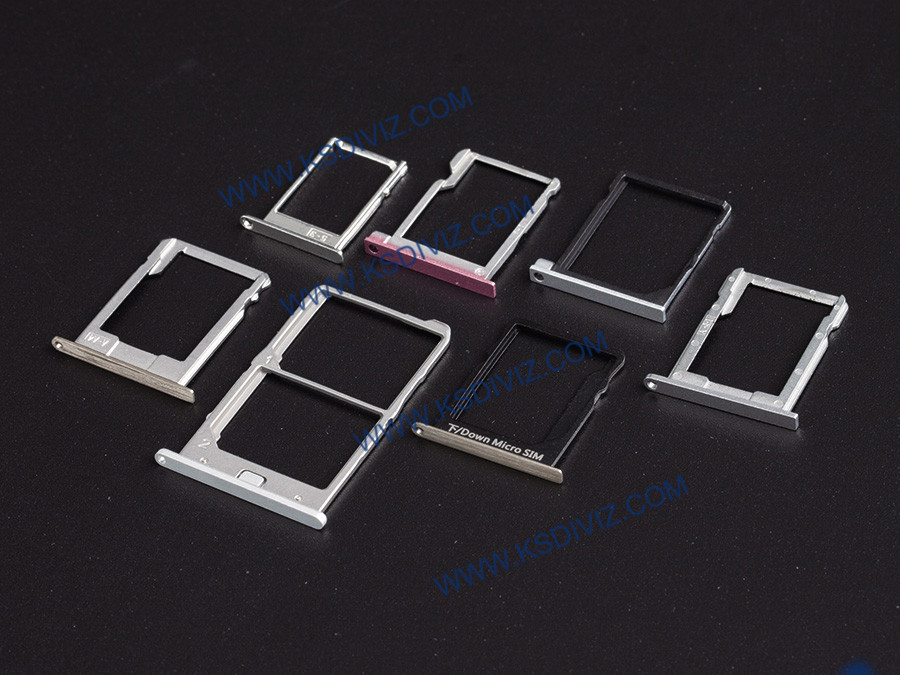

iphone product related parts…

Mold parts for acoustic prod…

Steel parts

Industrial control mold

To create cost-effective high-precision

parts products manufacturer

138-1293-1712

The company was founded in 2010, and has been accreditation of ISO9001 quality management system, TS16949 certification and high and new enterprise qualification.

2 Japan FANUC CNC engraving and milling machine, 4 sets of Taiwan to CNC, 4 Japan Sadegh mirror spark machine, 2 sets of Swedish hexagon three dimensional detector, strictly control the accuracy in - 0.002MM within.

A professional team led by professional engineers for more than 10 years of mold design and manufacturing experience. More than 10 die engineers have an average of more than 10 years of experience in the mold field.

Founded in 2010, after many years of continuous development, it has been widely recognized by customers, peers and society. ISO9001 quality management system certification, TS16949 certification and qualification evaluation of high-tech enterprises have been achieved.

There are people in charge of quality control from the plastic mold design to the mold opening and the injection molding.

With the professional customer service and business, the merchandiser system and our cooperation, you can be absolutely relieved; more than 10 professional after-sale service teams, 24 hours actively respond

Win the favor of the large enterprises with the quality

1. understand the plastic melt flow behavior, considering the resistance of plastics in runners and …

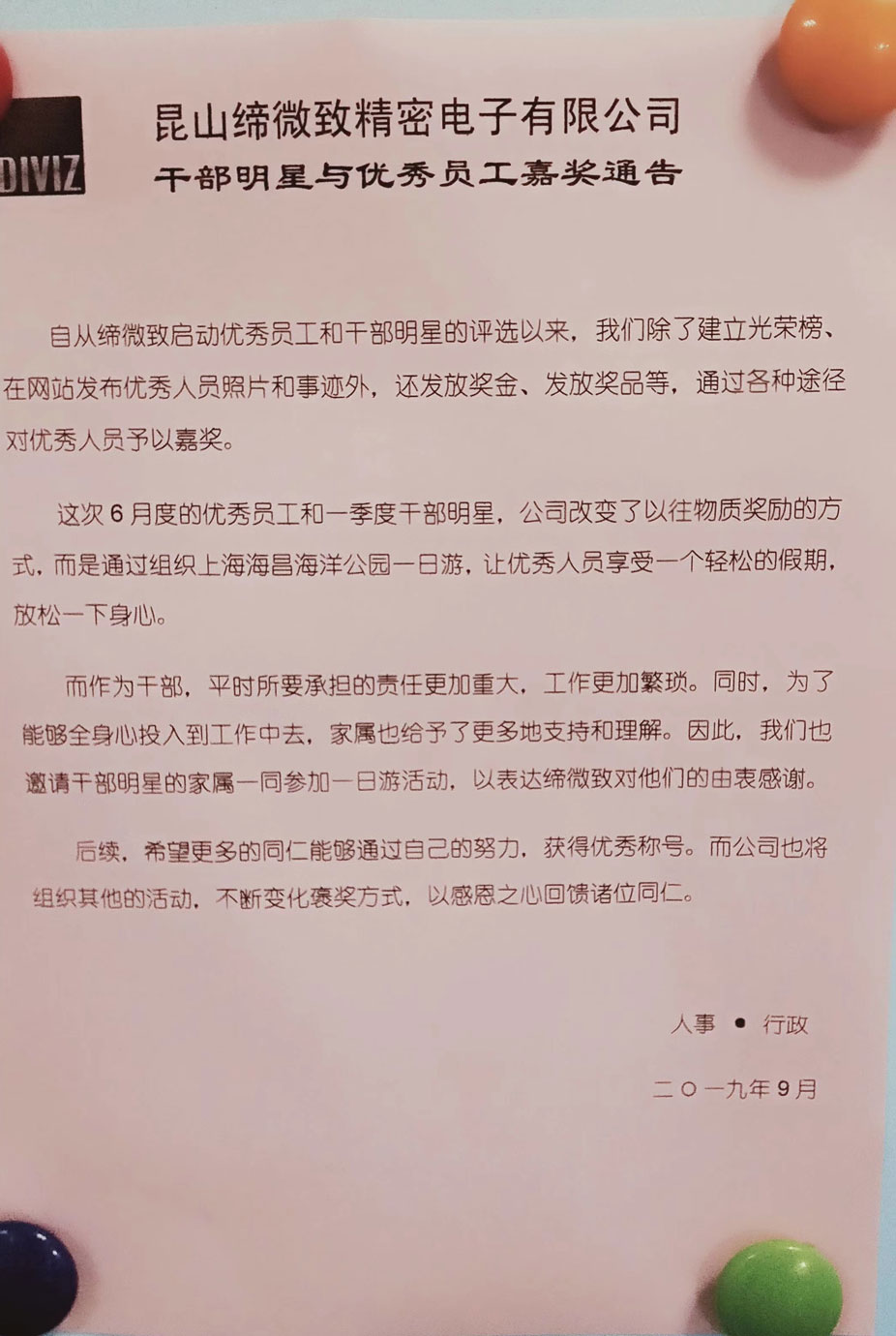

Excellent staff from grinding/CNC/EDM are awarded Shanghai one-day trip.

What is stability? The stability is divided into process stability and production stabilit…

1. Wear resistanceWhen the blank is plastic deformed in the mold cavity, it flows and slid…

The main effects of the dimensional precision of the plastic parts are as follows:1.Error …